Our new tooling supplier just sent us a full report with the required casing molds modifications to achieve the desired high quality standard we aim for.

Based on the report, we only need to make some severe changes in one of 3 molds, and some light modifications in the other 2 pieces.

Great news is that the new supplier assured high priority in execution and delivery.

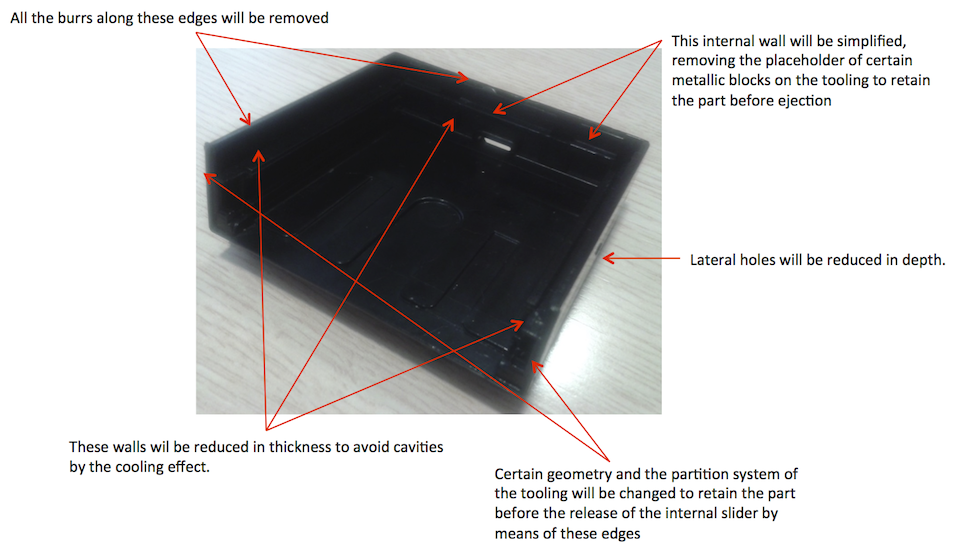

Please appreciate below the full extent of required changes:

Main Casing/Enclosure piece :

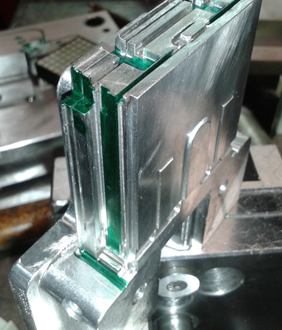

The first change affects to this part of the tooling, to conform the wrist strap holder. It must be refined and some welding deposits shall be removed and polished. Check the picture below:

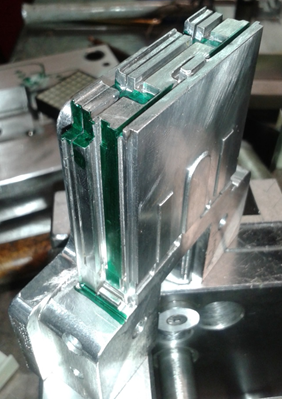

Major changes on the main slider described are going to be achieved by adding material in the areas marked in green in this picture below:

Transparent piece and cap piece molds.

Small diameters adjustments and needle addition to facilitate gases escape.

Clamping nails final adjustment

Complete polishing on transparent sides and final texturing .

By accomplishing all these changes, we should finally have an enclosure unit with the high quality standard we envisioned when this journey began .

According to our new provider timeline, they are going to need about two weeks to work on all the above changes, and another week to produce all units; that gives an final estimate of 3-4 weeks.

As you can see, it seems like we are finally in the right track and moving at a good pace, and we will make sure this time to show the advancements as we receive updates and images from the supplier.